Tires for Farmers

Every farmer, whether big or small, needs the right tires to match their specific farming needs. The selection of tire designs used on farms can be overwhelming, but OK Tire Stores offer a wide variety of tire brands, sizes, plies, speed ratings, and tread patterns to fulfill all your requirements.

We recognize that time is crucial for farmers, and any downtime can lead to a loss of income. That’s why we offer on-site and in-field service to keep you moving forward. Our skilled agricultural tire technicians have received extensive training to safely provide efficient service that meets your needs.

Services We Offer

- Proper Tractor Setup: To achieve optimal performance on the field or road, proper setup is necessary when installing a new set of tractor tires. This includes considering factors such as air pressure, vehicle weight recommendations, and tire component matching.

- In-Field Service: Elite Tire provides fast in-field service when you need tire service. Our skilled technicians are equipped to handle any tire-related issues that may arise.

- Troubleshooting Ride Issues: Experiencing tire-induced vibrations, radial hop issues, or lead/lag issues? Our tire technicians have extensive experience and training to troubleshoot and address these ride issues, which are commonly found in mechanical front-wheel drive or mechanical all-wheel drive tractors. If your tractor is “hopping” in the field, we can help.

- IF or VF Tires: New tire manufacturing technology allows agriculture tires to carry the same loads at reduced air pressure, resulting in better traction and less soil compaction. Proper air pressure is crucial for these new technology tires, and Elite Tire can recommend the optimum air pressure for fieldwork.

- Rims and Hardware: Elite Tire provides a wide selection of rims and hardware for your equipment, including custom fit and dual/triple hardware.

Central Tire Inflation Systems Division - CTIS

What is CTIS?

Equipment is huge these days—as heavy as dinosaurs—and can leave an unwanted footprint on your farm’s profitability. Severe soil compaction leads to lower yields and other problems, too.

You can fight back by running your tire pressures as low as safely possible in the field. But then you’ll just run into another problem: You need to set your tire pressures based on weight and speed. High for road travel. Low for fieldwork.

And this is where Central Tire Inflation Systems come in. With CTIS, you can adjust the ideal tire pressure for the road or field without touching a dial. There’s no other practical way to optimize your machine’s tire pressures (and footprint).

Benefits:

- Increase your yields

- Improve fuel economy

- Improve ride and handling

- Extend tire life

- Safeguard your soil for years to come.

Road Pressure

High PSI = Low Rolling Resistance

- Better Fuel Economy

- Longer Tire Life

- More Secure Handling

Field Pressure

Low PSI = Large Footprint

- Higher Yields & Less Compaction

- Faster Working Speeds

- Better Fuel Economy

- Improved Ride Quality

No Danger of Downtime Due to a Flat Tire

The last problem you want from any technology is downtime. So, here’s the exciting news: Every PTG system is a two-line system. This means that there are control and supply air lines running to each tire. So, if an airline breaks for some reason, the tire stays inflated.

Other inflation systems on the market are single-line systems. If you lose an airline on a single-line system, you’d have to leap out of the cab like a gazelle to close the valve manually before your tire goes completely flat. Not fun unless you’re an Olympic veteran.

10,000-Hour System Lifespan

Another benefit of PTG’s two-line design? The system is only pressurized when it’s adjusting the tire pressures. This means that PTG systems have a proven 10,000-hour lifespan.

Were you expecting to uncover something flashier at the heart of our inflation systems? You probably agree with our feelings on this one: It’s not flashiness that makes a difference. It’s reliability. And the positive impact on your bottom line. Those matter any time you’re evaluating the ROI of any product for your farm.

Case Study:

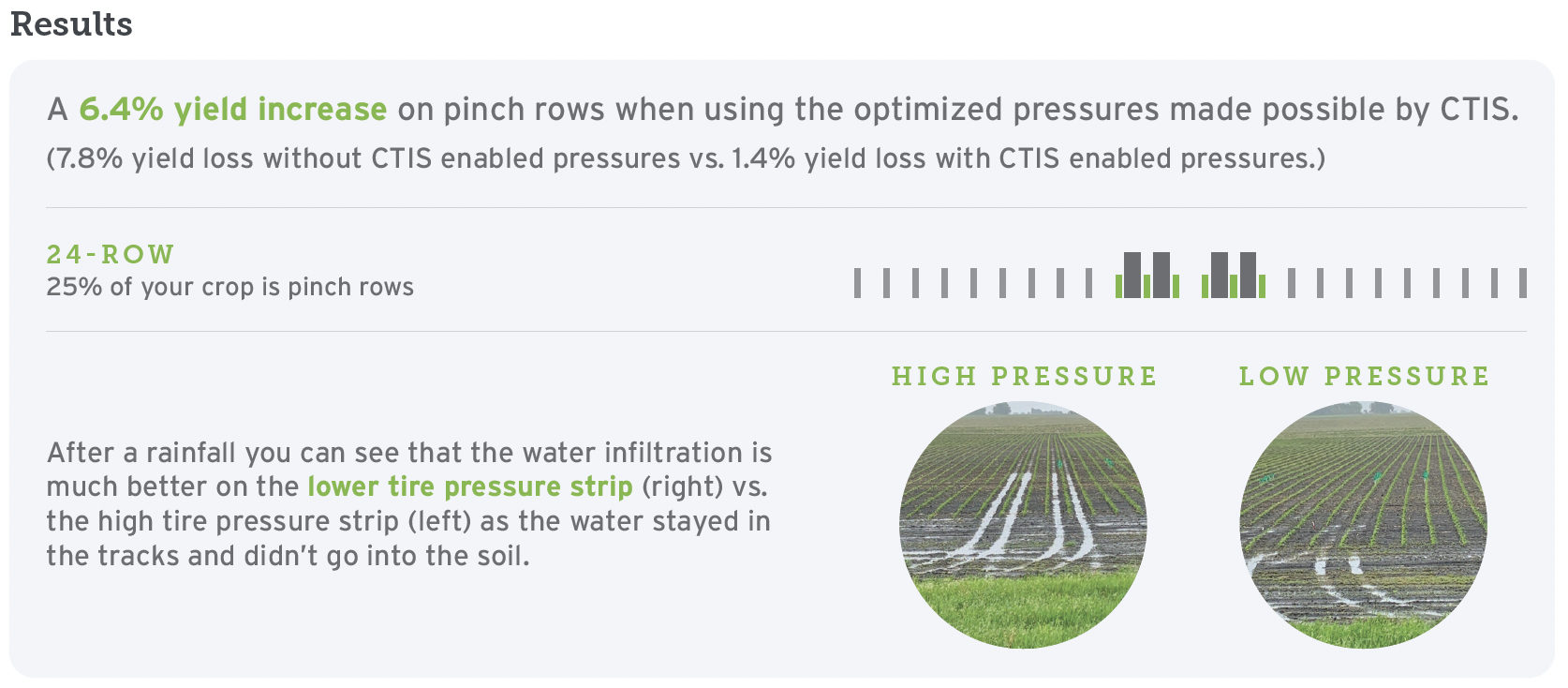

Planters are notorious for causing pinch-row compaction, which causes restricted root development on the center 6 rows beside your planter’s transport tires and tractor’s tires. A 2021 Michelin study found a 6.4% Yield Increase with CTIS. And there have been multiple other studies with similar results.

Many farmers who are looking to equip their planters with CTIS choose to mount their systems on their planting tractors. Every PTG system can control and adjust the tire pressures on three axles. So, a tractor-mounted system can also control a planter’s tires if it’s equipped with the CTIS hardware.

- Center-fill planter

- Sprayer (self-propelled or pull-behind)

- Tractors

- Manure tankers/spreaders

FAQ's: